About Euro Air

Since 1991, we have been transforming spaces into healthy and pleasant environments.

We were pioneers, introducing textile ventilation systems to many markets. In 2007, we became part of the KE Fibertec Group, one of the largest companies in the field of textile-based air distribution systems.

Despite our global reach, we remain true to our roots. All production still takes place exclusively in the Czech Republic and Denmark, ensuring consistent quality and a responsible approach.

About Euro Air

Already in 1991, the Danish engineer Niels Erik Thomsen came up with the idea that HVAC systems could offer much more than just temperature and airflow regulation.

In 1991, Niels Erik Thomsen decided to go his own way. He had years of experience in the HVAC industry, but was becoming more and more aware that the market approach at the time was not meeting the real needs of customers. He believed that HVAC could do more than just regulate temperature - it could make people's lives better.

And that's why he established Euro Air. His aim was to develop systems that make breathing easier, improve the environment in which people live and work, while offering modern and sustainable solutions.

The early days were not easy. Mr. Thomsen had to overcome challenges and build something that was at the time completely new. But he believed in his vision and it was worth the effort. What started as one man's dream has grown into a company that has become one of the leaders in the HVAC industry - known for its innovative and reliable solutions.

Family weaving mill

Guarantee of quality from generation to generation.

We weave the material for our air conditioning systems directly in our own family-owned weaving mill. This makes us the only manufacturer in the world to use our own woven materials.

The KE Fibertec Væveri weaving mill is a family-run business with a long tradition. Today it is run by the third generation, Mr. Frank Hansen, and the entire production focuses exclusively on fabrics for air distribution. This close specialised focus allows us to guarantee not only high quality, but also precise technical parameters tailored to each project.

Unique software for designs

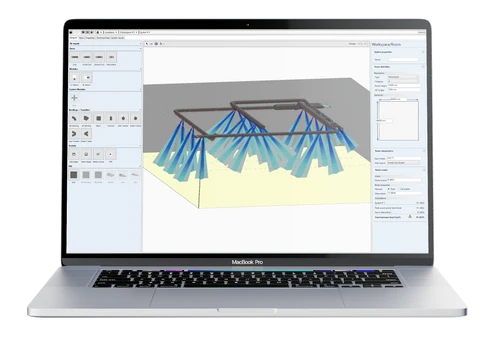

For the design of textile ducts we use TBV Designer - software specially developed for this purpose.

This advanced tool allows us to precisely take into account the specific requirements of each project and provide you with detailed technical documentation including drawings and visualizations.

With TBV Designer, you can easily imagine how your system will work, whether it's cooling, heating or fresh air distribution. The software works with parameters such as:

- Incoming air flow,

- the required pressure drop,

- the technical requirements of the space.

With TBV Designer we will design a system that perfectly matches your needs

We are experts in air technology.

Our R&D department and the weaving mill are only a few steps apart, which allows for perfect collaboration.

In our state-of-the-art laboratory, we carry out smoke tests, among other things. These help us to prove the quality of our products and new developments. In this way, we can guarantee that everything meets the technical parameters we promise.

The combination of research and production allows us to deliver solutions that not only work, but meet your expectations in the long term.

We care about the future

Sustainability is not just a phrase for us, and we are proving it with many steps.

We recycle textile waste, reduce our carbon footprint and use renewable energy in our manufacturing. In 2015, we launched the textile ducts certified to the Cradle to Cradle standard.

And our commitment goes beyond conventional standards. We are constantly looking for ways to be more environmentally friendly while offering products that deliver real value.

Euro Air

Have a look at our production

Get in touch with us

The refreshing air you desire is just one click away.Our expert sales representatives are ready to advise you on design or handle any project.

With us, you can expect a response to your request within 24 hours.